User's heat exchanger tube sheet expansion work site:

Tensile test effect of strength expansion sample:

YZJ series rapid expansion machine is a special expansion equipment for manufacturing and maintenance of boilers and heat exchangers. The equipment can reliably expand heat exchange tubes of various specifications and materials, especially for thick tubesheet and large diameter tube heat exchanger. The heat exchanger produced by using the expansion technology of the rapid expansion machine has the advantages of uniform expansion, safety and reliability, long service life and low failure rate. Moreover, the expansion operation is simple and the expansion speed is fast, which greatly shortens the manufacturing or maintenance time, reduces the production loss of chemical plants, and has high economic benefits.

YZJ hydraulic expansion technology has the following characteristics

1. The tube sheet of any thickness shall be uniformly expanded at one time in full thickness.

2. Expand the intermediate tubesheet or multi tubesheet heat exchanger at any depth.

3. Expanding the internal thread pipe or welded pipe.

4. After expansion, the residual stress is low, and gap corrosion is not easy to occur.

5. The axial direction of the heat exchange tube is not stretched but slightly contracted after expansion, which is conducive to reducing operating noise.

6. The inner hole error of the pipe is large, and the diameter of the expansion head can be properly adjusted on site (the maximum grinding allowance of the expansion head is 0.3mm).

7. The expansion joint shall be free of oil pollution, and the expansion before welding shall not be affected.

8. The edge of heat exchanger with tube box can be expanded directly, which is very convenient.

9. Single person can continuously expand 6-8 pipe heads per minute.

10. The comprehensive economic benefits have been greatly improved.

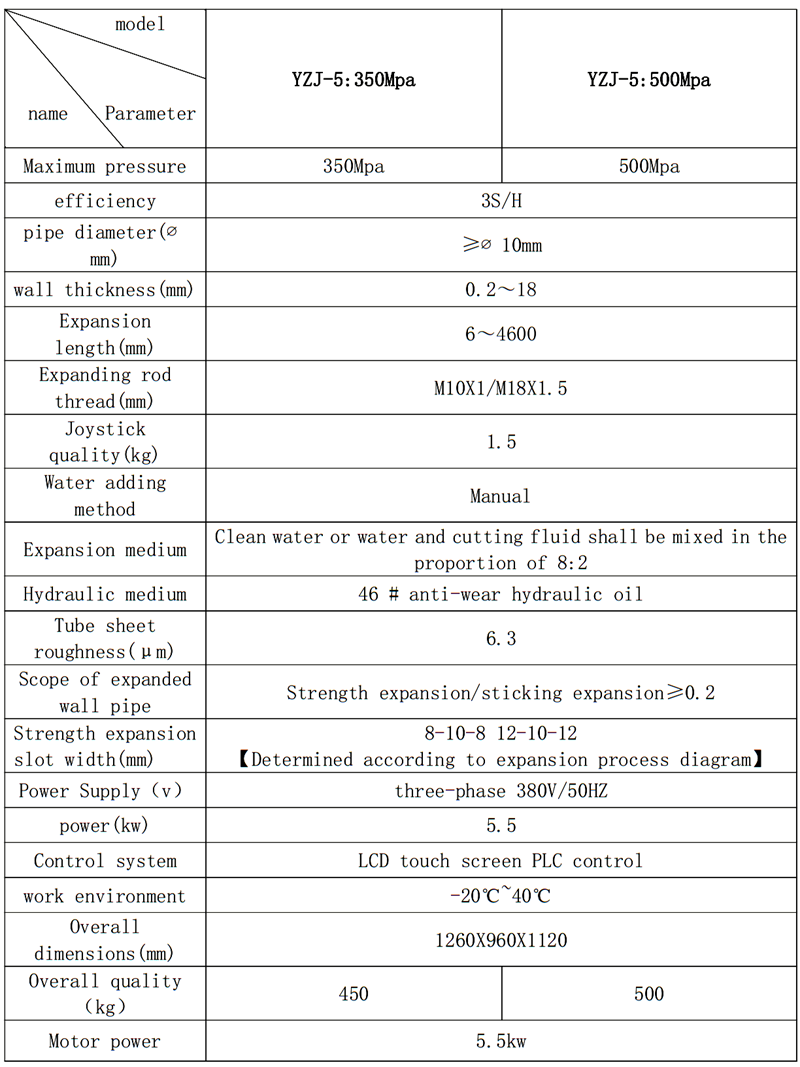

Main technical parameters:

Note: website information is for reference only, subject to offline communication and confirmation!

Conditions of Use

1. Indoor use.

2. The ambient temperature ranges from - 20 ℃ to 40 ℃.

3. The monthly average maximum relative humidity in the use area is not more than 85%, and the monthly average temperature of the month is not more than 30 ℃

4. There is no conductive dust, explosive gas, or corrosive gas that can seriously damage the insulation of the metal box.

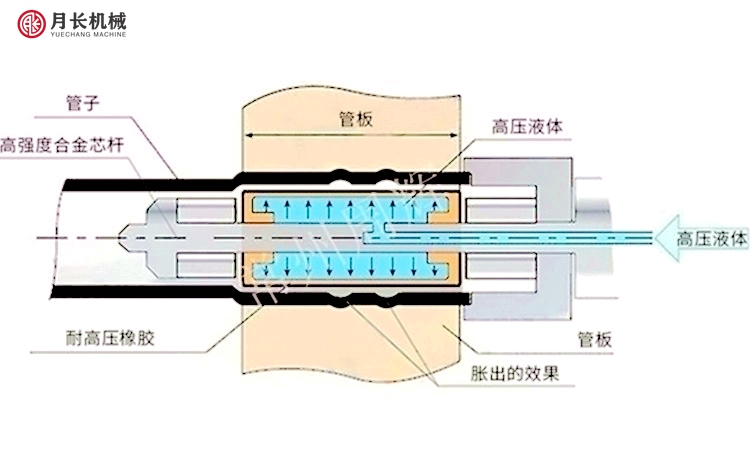

Structure and working principle

1. Structure of tube expander

The hydraulic pipe expanding machine is mainly composed of hydraulic control system, pressure amplification system, hydraulic pipe expanding control system and automatic water feeding system.

working principle

The hydraulic pump is driven by the motor to pump the hydraulic oil into the hydraulic control system for pressurization, and the pressurized expansion medium is sent to the operating handle through the high-pressure hose, thus exerting pressure on the expansion joint. The pressure setting is mainly used to set the pressure required by the user through the touch screen. The expansion medium pressure during operation is transmitted to the digital analog conversion module through the transmitter. The pressure value is displayed in the "current pressure value" on the touch screen. When the current pressure value is equal to the set pressure value, the depressurization system works to relieve the pressure, and the entire expansion process is completed.

The liquid bag type hydraulic tube expansion technology uses the pressurization principle to generate an ultra-high pressure tube expansion pressure that is sufficient to cause plastic deformation of the heat exchange tube. The pressure acts on the inner wall of the heat exchange tube through an elastic liquid bag, causing plastic deformation of the heat exchange tube, and produces interference with the tube sheet, which is then expanded into the tube sheet hole. With the hydraulic pipe expander and hydraulic pipe expander head provided by Changzhou Zhouhui, the expansion processing process is extremely simple. After the pipe is inserted into the tubesheet and assembled, insert the expansion head into the appropriate position in the pipe hole, press the pressure rise button of the expansion operation handle, and the pipe expander can automatically complete the pressurization, pressure maintenance, pressure relief and other work processes of the expansion according to the set expansion pressure.

To sum up, the liquid bag tube expander is a kind of hydraulic tube expander, which belongs to the flexible expansion process.

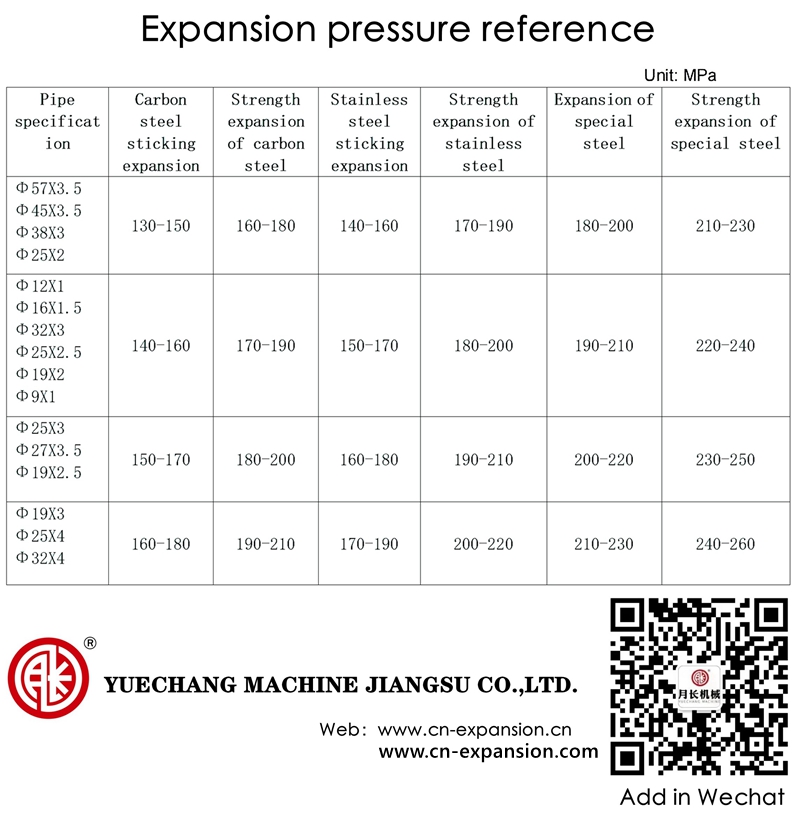

Expansion pressure value of conventional tube sheet and heat exchanger (reference)

notes:

1. Tube plate material of heat exchanger: 16Mn (15CrMo can be referred to)

2. The strength expansion shall meet the grooving requirements: the groove width shall be 8-10mm. Due to different materials and groove widths, the expansion pressure can be adjusted according to the degree of "depression" after expansion test.

3. Specification of other heat exchange tubes: under the condition of the same material Ф Outside/ Ф The internal ratio (i.e. wall thickness coefficient) determines the expansion pressure value. The larger the wall thickness coefficient, the higher the expansion pressure, and vice versa. The expansion pressure value of heat exchange tubes of other specifications can be determined by Ф Outside/ Ф The value of internal ratio is calculated with the value close to the center of the above table.

4. If the material of tube sheet and heat exchange tube is different from the above, or there are special expansion requirements, it is recommended to conduct expansion process test first, and the test results shall prevail.

Special instructions:

1. Expansion medium: antifreeze, water or water and cutting fluid shall be mixed according to the ratio of 8:2;

2. When replacing the operation power supply, a professional electrician is required to check whether the wiring is correct. Open the cabinet board where the machine touch screen is located, and the indicator light on the relay shows green, indicating that the wiring is correct;

3. Check the anti-wear hydraulic oil condition of the oil tank before expansion, whether the oil quantity is enough [at least above two-thirds of the oil level of the oil tank level gauge], and whether the oil is in good condition;

4. When replacing the expansion head, you must remember to fill up the water, boost the pressure and drain the air [it takes about 10 seconds to increase the pressure, and you can judge whether it runs to the top by the sound of the cylinder], reduce the pressure and absorb water [it takes about 20 seconds to absorb water], and repeat the lifting and depressurizing actions for 3 times to drain the rigid body air and fill the expansion medium. The water adding action is to stop the action of depressurizing [depressurizing is to absorb water];

5. If the expansion head is not inserted into the tube plate hole at the predetermined position, do not click the pressure increase button;

6. The expansion part of the expansion head must be in the tube sheet and inside the tube before expansion;

7. During tube expansion, the expansion head can be pulled out only after the pressure is completely relieved. The expansion pressure is not completely discharged Do not pull out the expansion head before removal. When inserting or pulling out the expansion head, it is forbidden to twist the expansion head.

8. It is recommended to start the oil pump and heat engine for 5 minutes before expansion;

9. The seal between the expansion head and the expansion gun is hard contact. When replacing the expansion head, the cone surface of the expansion head must expose more left-handed nuts. It is recommended to ensure that the left-handed nuts are at least 4 away from the cone surface of the expansion head to the thread.

10. The burr on the inner wall of the nozzle shall be cleaned to prevent scratching the expansion head;

11. During expansion welding, do not stand opposite the expansion gun.

12. Cut off the power supply before leaving after expansion.

Detailed information and operation method can be obtained by email

Email: kxbg365@qq.com

WeChat:czzhouhui